+852 2363 2511

When it comes to nailing that perfect powder coating job, one thing is crystal clear - the star of the show is your coating gun. A top-notch powder coating gun can lay down the powder just right, ensuring a durable and flawless finish. But, with the market flooded with an array of powder coating guns, the big question is, how do you pick the one that's tailor-made for your project? We've got you covered with some key considerations. Let's dive right in with the first crucial factor - the coating material. The type of coating material you're working with has a direct impact on the kind of coating gun you should be aiming for. Here's a pro tip: some coating powders demand a higher voltage for that sweet spot in transfer efficiency. Take polyester powder, for instance; it craves a high-voltage gun. On the flip side, a polyurethane powder coating prefers a low-voltage gun and a gentler touch. It doesn't stop there; the type of gun you choose also hinges on your target coating thickness. If you're aiming for thick coatings, you'll want a cannon-like gun with a hefty powder output and a broad spray pattern.Coating Material

Next up, let's talk about project size. The scope of your project is another game-changer. Some projects demand a big-time powder output, and for those, you'll need a coating gun that can deliver with speed and efficiency. Picture this: you're coating a vast expanse; you're going to need a bigger gun in your arsenal compared to a smaller-scale project. And remember, comfort is key, especially if you're going to be wielding that gun for extended periods.

Moving along, let's explore the complexity of your coating job. If you're going for a sophisticated coat with a medley of colors or special effects, you'll want a gun that can handle the intricacies. The same goes for the size and shape of the surface you're coating. They're the bosses of the spray pattern. Bigger surfaces might demand a gun with a wider spray pattern to cover ground efficiently, while those intricate, curvy surfaces call for a gun with precision and adjustability.

Speed demons, this one's for you. The application rate is a deal-breaker. If you're all about getting that coating on fast and efficient, then a high powder output gun is your sidekick. But here's the twist - the application speed has a say in the spray pattern. High speed equals a wider spray pattern to ensure even powder distribution. And if you're aiming for the fast lane, an automated system might be your best bet; it's like the race car of powder coating guns, zipping through the finish line.

Now, let's talk logistics. Your workspace needs to accommodate the powder coating gear. Safety standards are the name of the game, and it's not just about the size of the equipment. You've got to leave some elbow room – at least 3 feet between your gear and the walls, and the same up top between your equipment and the ceiling. Don't forget to check for any hoses or sprinkler systems hovering above the curing oven; you don't want a wet surprise mid-coating!

Last but not least let’s address the elephant in the room. The price. When considering a powder coating gun, it's important not to overlook the cost factor. These guns come in types: Corona, tribo or electrostatic. Corona guns are more affordable. May not provide that smooth finish you desire for intricate patterns. On the other hand, electrostatic guns are considered top tier options as they offer control over the coating process and deliver excellent results. However, if your budget is tight at the moment there are still budget options that can get the job done.

Selecting the powder coating gun requires a balance between factors such as coating material, project size, application speed and of course cost. Conducting research can be immensely helpful when navigating through the array of powder coating guns available in the market.

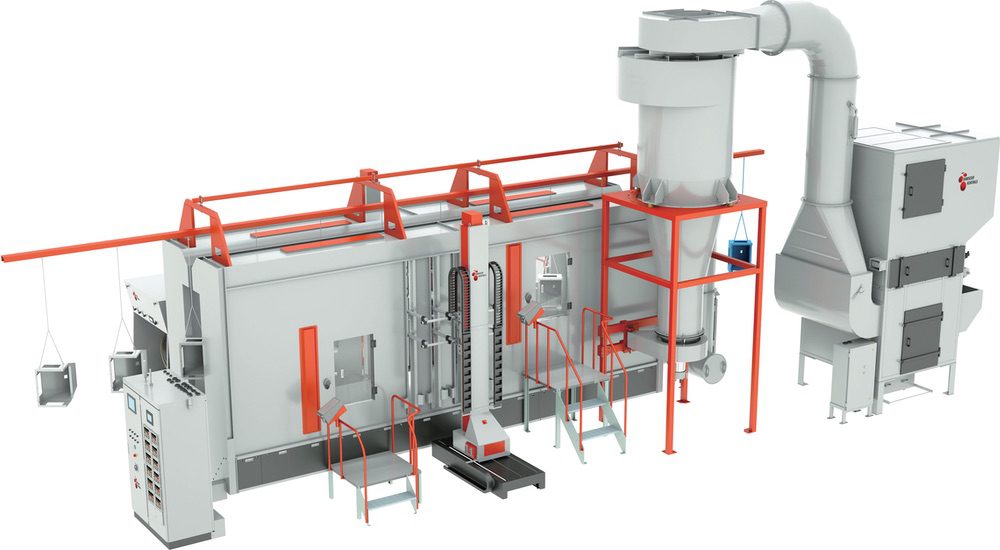

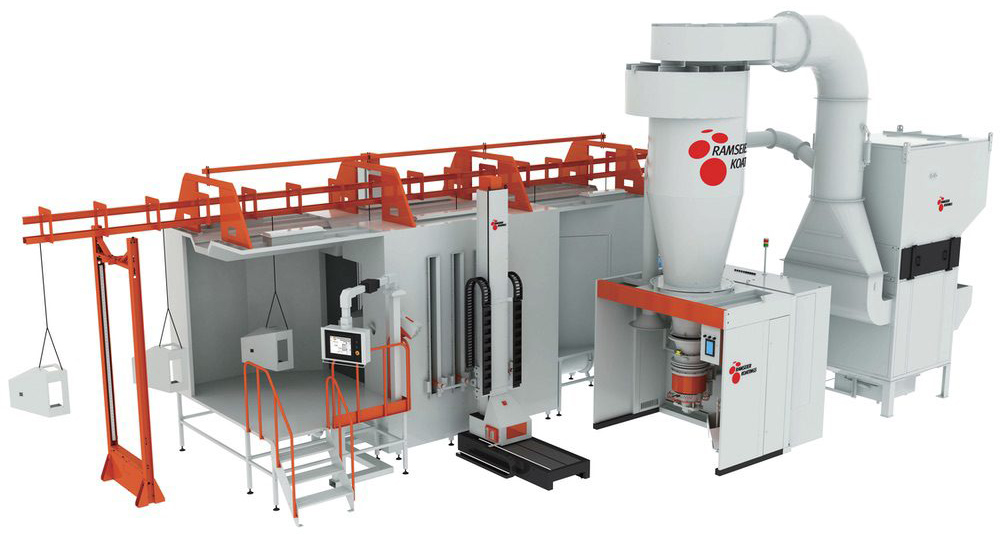

At Ramseier Koatings we've got you covered with a range of powder coating equipment that has been garnering attention in the industry. Our products prioritize style, versatility and affordability while incorporating cutting edge technology.

Think color matching and enhanced transfer rates; these are our ingredients, for maximizing your profits. To make it even better we have a range of accessories and materials that will make your powder coating project incredibly easy.