+852 2363 2511

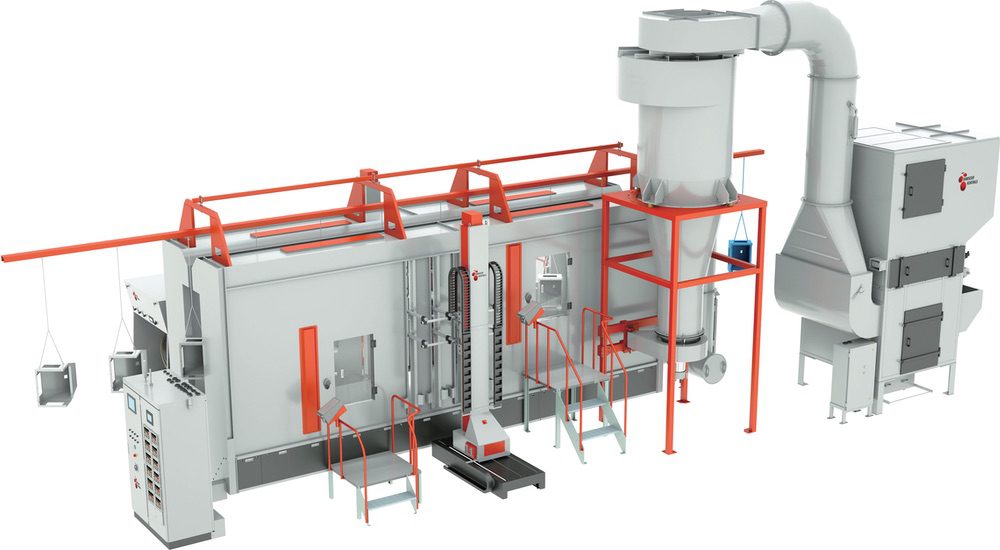

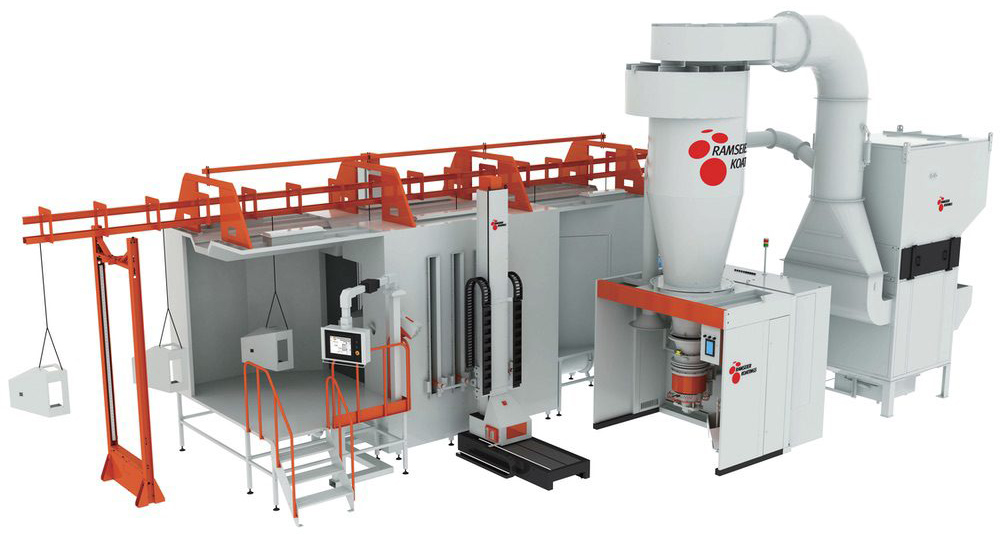

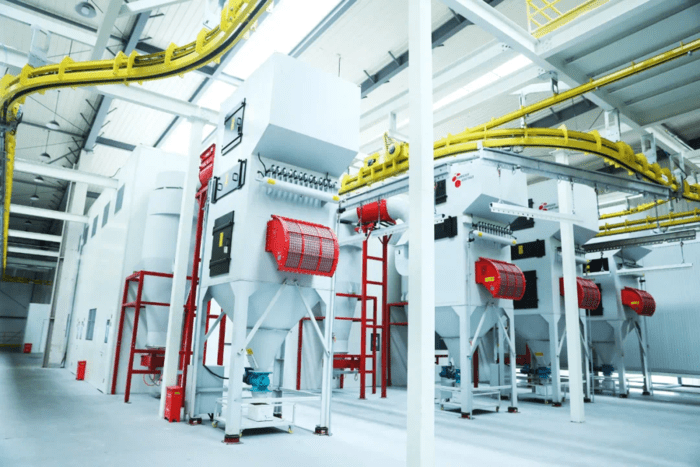

In the powder coating industry, an automated system (sometimes called a computerized line) is used to transport components automatically between each process stage. In most cases, this involves washing the parts with a chemical solution, drying them, adding the powder-coating material, curing the powder-coated finish, and finally letting the components cool.

As the components travel linearly from one device to the next, all operations are performed on the various features concurrently. In contrast, a batch system requires the operator to physically prepare and amass pieces before they are coated and cured in batches.

The process of selecting new powder coating equipment may appear daunting at first. Similarly, choosing a company that provides powder coating solutions may seem more complicated than it is. Thus, how do you recognize a high-quality powder coating machine? This piece of guidance:

With thousands of identically sized parts moving through a facility every shift, automation is your best bet. The value of an automated powder coating system like this often increases.

You shouldn't skimp on tools if you apply powder coating by hand. Considering your other expenses, it's tempting to spring for a less expensive spray gun. But doing so could end up costing you more in the long run. Be careful to invest in high-quality machinery for the long haul. Having reliable tools that can withstand repeated use is essential. Don't just choose the cheapest one.

Because of their reduced physical footprint, batch processing systems are ideal for space-constrained businesses.

It is a question that many individuals overlook asking throughout a search. Nonetheless, it would help if you inquired as to the criteria they use when choosing employees and how they deal with each client. In their view, what constitutes good customer service?

Determine the company's specialty and if it holds membership in any relevant groups. Do they offer much except powder coating? In that case, they are likely using fewer cutting-edge tools available.

Batch processing is recommended if the coating phase of production takes longer than the rest of the manufacturing process. An automated method could be helpful if the powder coating process is slowing production.

Coating many identical things in a short amount of time is possible since components need not be moved between processes. Painting a steady stream of parts at a rate that can't be matched by hand is only possible with an automated line built for high throughput.

It would help if you were ready to get a feel for their modern tools. Technology advancements in powder coating applications have been quick, so the firm you choose to work with should be open and honest about the methods they employ and the specifics of the machinery used to apply the powder coating.

Regarding powder coating equipment, we've done the bulk of the legwork for you. You may launch your company with minimal fuss by using the most popular dimensions for your most common products.

Please inquire if the size you require needs to be listed. Wash stations, pretreatment stations, blast rooms, and automated finishing lines are just some of the hundreds of product sizes we carry. You can also count on us for a tailored solution to your unique needs. Ramseier Koatings is an excellent resource for finding the necessary powder-coating machinery.