+852 2363 2511

Powder coating technology, a surface finishing technique well recognized to possess the inherent characteristics of durability, appealing aesthetic nature as well as the eco-friendly benefits to surfaces, is gradually being realized, adopted by industries in the quest for increased profitability. The major problem that faces powder coaters is reducing the production cost elements to increase the profit margins. Wastage, power consumption, equipment maintenance and labor costs pose as huge enemies to the profit line. This regards, basically, state-of-the-art strategies and technologies that reduce the costs of production while increasing the efficiency in the operation of powder coating processes.

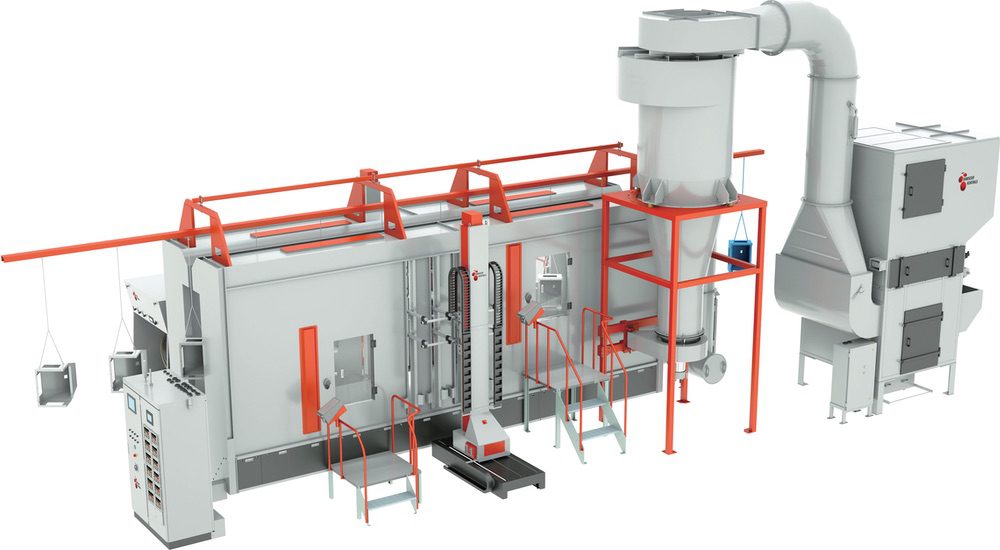

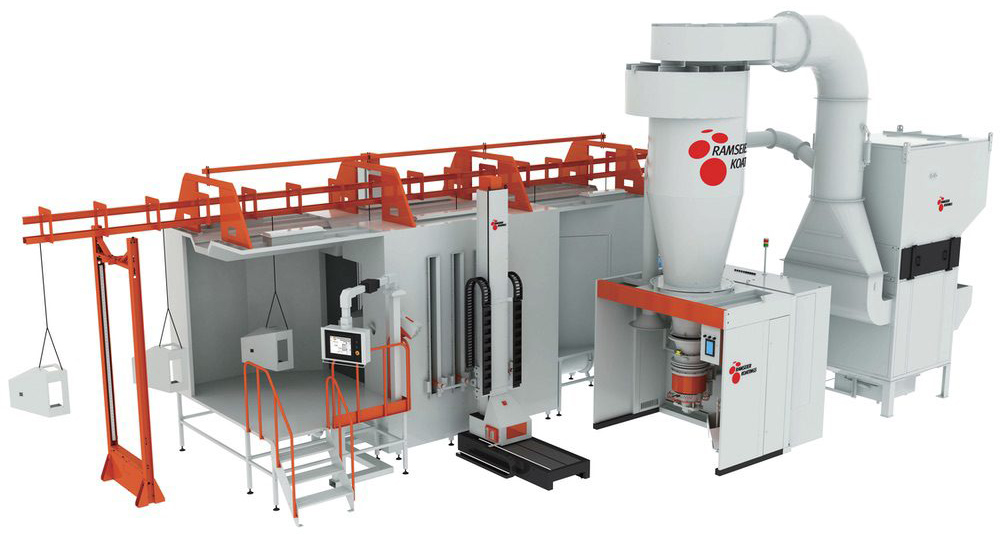

One of the big considerations of the cost of powder coaters will arise from material waste, where traditional liquid painting techniques fall prey to overspray and significant losses of materials. In sharp contrast, the powder coating offers a sustainable option that is rising fast in the market. Such technological advancements include the use of electrostatic guns and automated systems that enable better control throughout the coating process or operation. Research by the American Coating Association points out that electrostatic spraying techniques are highly effective at achieving transfer efficiencies of up to 98% and can reduce overspray and increases material utilization significantly.

The other key powder coating cost variable is energy consumption. This aspect of powder coating has been revolutionized into energy-efficient mediums with breakthrough technological events, such as the introduction of powder-coating ovens that incorporate either infrared or convention heating systems.

In fact, reports state that the energy consumption of powder coating ovens with an infrared heater can be as much as 40% less than conventional ovens. This signifies a substantial avenue for powder coating plants to achieve noteworthy financial savings.

Keeping equipment in tip-top condition should guarantee that no big maintenance or cost of purchasing new equipment is incurred to achieve quality product delivery. From cleaning gun nozzles to inspecting the powder recovery systems to lubricating the machine moving parts, these simply routine maintenance practices help avoid costly repairs and assure all the machines perform at optimal conditions. On the other hand, durable and quality machines will mean an overall reduced cost for maintenance by as much as 30% over the life of the machine. The implication is too direct to be ignored: those wishing to cut down costs on maintenance will have to settle for endurance and predictability.

In most cases, labor expense usually dominates the scene in the manufacturing cost environment. Though manual powder coating may require more skilled operators and long labor turnaround time as compared to automated processing, its benefits do outweigh this reality. Specifically, doing it manually is cheap in that one does not need a lot of capital outlay for the equipment. Automated and robotic systems are computer controlled and can execute high volume productions with much higher level or accuracy compared to humans.

The companies that have achieved robotic automation of their powder coating operations accomplish a noteworthy reduction of 25% in labor costs with related improvements in the throughput as opposed to when the activities are manually done. All these would justify that automation and particularly robotics has a storyline to play in adding value to an organization by reducing the general labor costs of coatings.

Controlled means in managing the production costs are extremely critical towards realizing long-term success and strengthening the profitability in the functional operation of powder coating. Introduction of high-end technologies in powder coating leads to minimizing the waste material and optimizing the use of energy but is risky to adopt because it's also capital intensive with regard to strategically investing in maintenance equipment and streamlining the labor costs through mechanisms established. This progressive approach does not only make the powder coating process cost-effective but also hikes up overall efficiency and quality of the process.