+852 2363 2511

Streamlining and optimization are essential if you are just getting into the powder coating business or looking to upgrade your existing finishing system. This is why the automatic powder coating technology is increasingly popular in different enterprises. There are several steps of the powder coating process, starting at pretreatment to curing, and you can easily adjust concepts of the coating system to meet varying finishing requirements.

Let’s get started on the main advantages of an automatic powder coating system to help you determine its effect on the performance and reliability of your products.

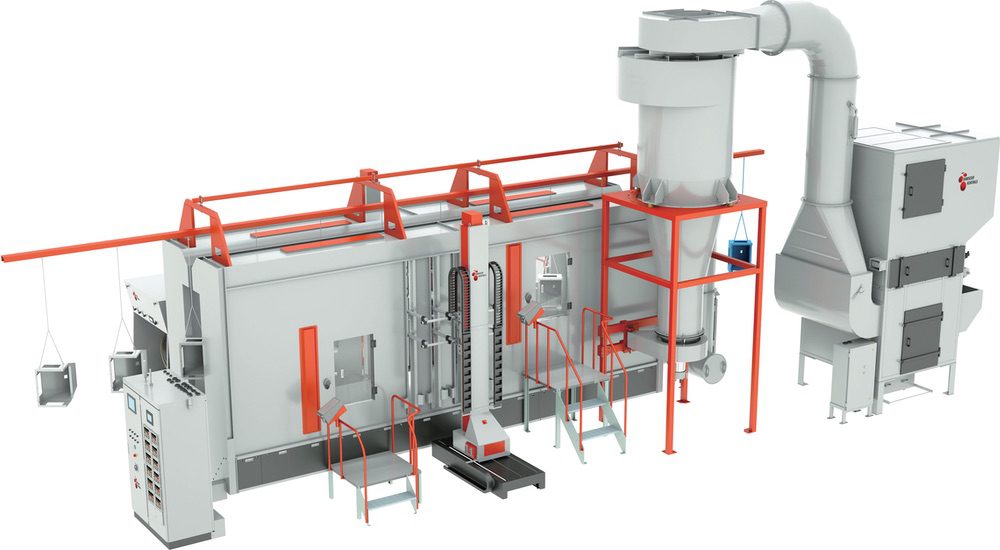

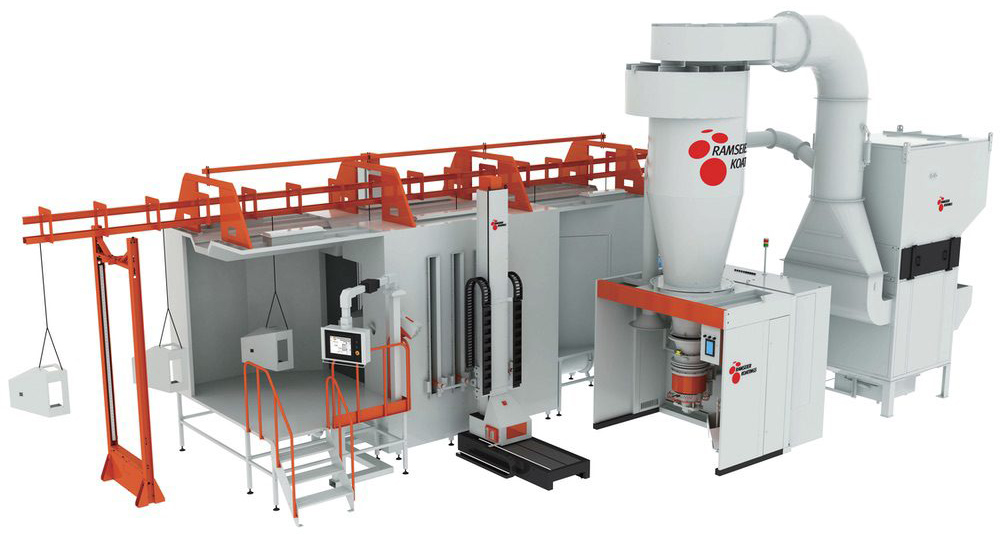

Manufacturers need an efficient way to enhance the visual appeal, durability and efficiency of metal parts. This is where automatic powder coating lines come in. It holds several components like a spray system, conveyor, oven, control system, etc., which have different roles throughout the operation.

The pretreatment machine contains systems like tanks, exhaust, pipeline, and bath liquid heating, which streamline the treatment processes. Other important processes involved are thorough cleaning and rinsing to enhance the quality of the finish.

Also, ensure you conduct regular checks for impurities on the nozzle and tank fluid to avoid clogging.

Maintaining a steady supply of finished goods can be challenging because of growing customer demands. That said, automatic powder coating systems stimulate productivity and significantly reduce finishing issues which are more likely to occur with manual labor.

A controlled process enhances worker safety and you can increase your production in your current space.

There are finishing options currently in the market which contain solvent components that can lead to the release of VOCs. Nevertheless, this is not an issue when it comes to automatic powder coating lines. They are more environmentally friendly and there is reduced waste during the process; you can reuse the coating.

The production of automatic powder coating systems is unmatched compared to manual solutions. They also help you achieve precise coatings and enhance the protection of surfaces. Overall, products finished using Automatic lines stand out in the market due to aesthetics and improved efficiency.

The size of your business and your customers' needs determine new equipment’s training time. A good thing about an automatic powder coating system is that it saves you the hassle of training the machine which saves on time.

Powder coating is done on the exterior of most parts. This is why you should avoid issues like dripping or uneven colors. Using an automatic powder line allows for a high-quality finish with optimum consistency.

The benefits of an automatic powder coating line make it an ideal choice for manufacturers. Some common uses are:

● Electric appliances - Electrical engineers use automatic powder coating as it works on varying sizes of electric appliances, including very small parts.

● Automobile sector - Automatic lines can be used to enhance the visual appeal of different automobile components like the chassis framing and body. It allows for uniform coatings of large bulks of vehicle parts.

● Machinery manufacturing sector - Automatic lines have common uses in the production of durable and reliable mechanical components.

● Building and Construction - a wide variety of metal parts is used while building normal residents or high-rise buildings. Automatic lines enable engineers to achieve effective and visually appealing designs.

There are different types of spray booths that you can use during the powder coating process. Whichever choice you go with should seamlessly fit into the production line. Incorporating batch booths is more straightforward as they are standalone units which you can use for large projects. Automatic powder systems are nearly fully automatic unlike the batch booths where you use a manual powder gun sprayer, making them more reliable.

Automatic powder coating systems come at a cost. However, the benefits they offer in different industries make them worth your money. Your powder coating process will have less waste of resources, produce top quality results and enhance the efficiency of the parts. Automatic powder coating systems require regular maintenance to ensure they stay in good working condition.

At Ramseier Koatings we are happy to help with any inquiries or supply you with an unmatched quality of Automatic powder coating systems. Contact us today for a prompt quote.