+852 2363 2511

Powder coating and electrostatic painting are two popular techniques for decorative coatings. Both offer benefits, including ease of application, high level of protection etc. They both work by using electricity against the surface of an object. However, both coatings come with their own unique properties. Indeed, the main difference between powder coating and electrostatic painting lies in their application processes. While powder coating may be applied in spray form, electrostatic painting needs a special tool such as Parker. Below we compare powder coating and electrostatic painting to help you pick what’s best for your project.

Powder coating remains a viable technique for boosting the aesthetic and corrosion resistance qualities in different surfaces. It engages the positioning of supercharged solid powder junkers over a grounded metal surface by an applied electrostatic sheet through thoughtful spraying. Excess powder is then selectively eliminated with an air gun during the application. The resulting curing process occurs through heating and imparts excellence vigor surpassing electrostatic painting.

The powder coating, notably, in contrast to the texture provided by its counterpart of electrostatic painting, was not only smoother but also provided one with a feel for the metal. This approach is extensively used in protective treatments to the components in industries of automotive, aerospace and medical devices where there is a serious concern regarding corrosion on various metal surfaces.

This special method of electrostatic painting creates a load between paint layers, on the other hand. By reason of this electrical energy, dirt is actively repelled away from it and consequently becomes less adherent to the paint surfaces. Therefore, this produces a surface where dirt can be gently wiped off or fundamentally be washed back off rather than being stuck onto the painted surface or needing for removal of original painting.

Electric painting makes use of brushes and sprays but is limited to non-porous types of surfaces like glass, wood, and aluminum. For most applications, the paint dries in a natural manner good enough with some requiring occasional low temperature oven drying.

Let’s explore the two, feature by feature.

Surface coating systems’ effectiveness is always a debate about powder and electrocoating. Both produce solid, tough finishes that require little maintenance than is the case with uncoated surface. However, a closer examination gives insights on the strength of both coatings in resisting abrading and corrosion elements.

The toughness of powder coat surfaces surpasses that of electrocoating counterparts due to heat treatment during powder coating. Unlike in electrocoating, it goes through curing process as well as heating which makes it harder.

One key factor to consider before choosing between these two types of coating systems is corrosion resistance. Electrocoats are known for having very high resistance hence are preferred in various industrial uses. But while powder coating is capable of providing protection against rusting, its susceptibility to wear and tear from corrosive agents like salt water implies the right choice should be made based on its use.

Electrostatic coating becomes exceedingly useful when dealing with complex or inaccessible areas. More uniform and complete coverage results from immersing components in liquid rather than using a regular spray gun. Also, it creates thinner layers for use as a priming coat before applying paint. This enhances corrosion resistance.

E-coating is notable in terms of economy. E-coating doesn’t have to use a specialized paint booth and an oven, unlike powder coating. It is highly versatile and can be done on site thus eliminating the need for an oven hence reducing initial investment costs. Previously, electrostatic painting supplies were expensive because the equipment was not readily available. However, this situation has changed with time as more suppliers have emerged.

Electrostatic painting is mostly preferred due to its high flexibility thus enabling a wide range of colors in comparison with powder coating. Producers are able to achieve complicated designs by applying several layers that carry electric charges. Electrostatic painting is the most appropriate for those who prefer either industrial aesthetics or long-lasting coatings that exceed five years old.

However, despite its advantages e-coating has challenges which are associated with it. Over-spraying may lead to imperfections such as hanging points on surfaces. Additionally, compared to powder coatings with a wide variety of textures such as fine textures, wrinkles, hammertoes or antique veins giving different visual and tactile effects e-coating does not offer many texture options.

When deciding between powder coating and electrocoating, it is important to draw a fine line. Powder coating is strong because of the way it is heat-treated while electrocoating has excellent anti-rust properties capable of making its application appropriate in large scale industries. In terms of practicality, for example, if you are concerned with cost-effectiveness and accessibility then the best option will be that which involves electrostatic painting for parts with intricate shapes

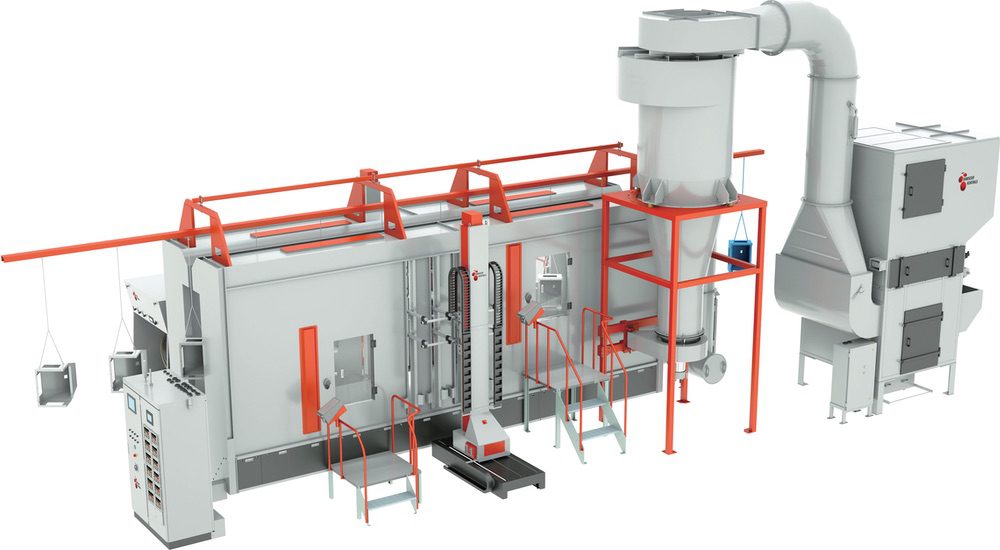

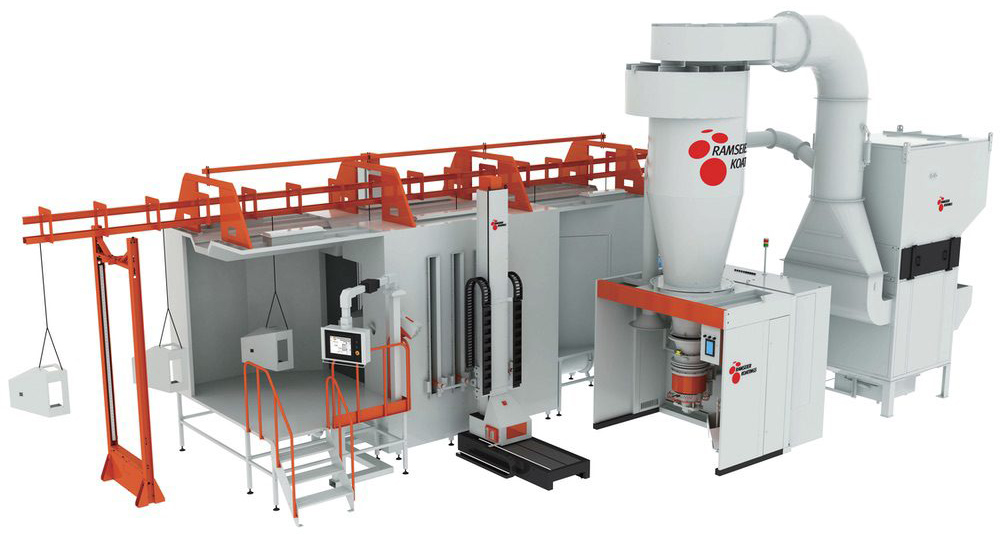

But despite the fact that electrocoating can be made to look more attractive than other types of coatings, it still presents us with some problems such as over-spraying and limited textures. The need for good choices makes industry-responsive systems critical in this travel. At Ramseier Koatings, you can select from our powder coating equipment to suit your needs and budget preferences. You can reach us on our website for an instant quote on these machines.