+852 2363 2511

Powder coating is now the talk of different industries. But with the benefits that its tags along with, we can't expect anything less from this electrostatic process. It is now being adopted in different industries to give surfaces a sleek, durable finish. We're talking metals, plastics, even wood. It’s a revolutionary painting approach. But hey, it's a bit more complex than that. So, if you are looking for those tips that will help you get the right powder coating machines, this article is here to guide you through. Read on!

First things first, let's understand what you're coating. If it's steel pipes you're dealing with, you'll want a powder coating machine that comes equipped with a high-speed airbrush nozzle. Plastic parts? Well, for those, you'll need a different nozzle, high-speed of course.

And if you're planning on giving your metal parts a few coats of that beautiful polyester paint, consider a one-shot coating instead of repeated spraying. Efficiency is the name of the game, my friends.

Now, what kind of coating are you planning to use? Different strokes for different folks, as they say. Ceramic coatings are the go-to for high-temperature applications, while intumescent coatings work like heroes when it comes to fire protection. And, of course, acrylic coatings add that touch of artistry to your projects.

But here's the thing – size matters, folks. You need to consider the size and weight of the parts you're coating. Luckily, powder coating machines come in various sizes, so you'll find one that fits your needs.

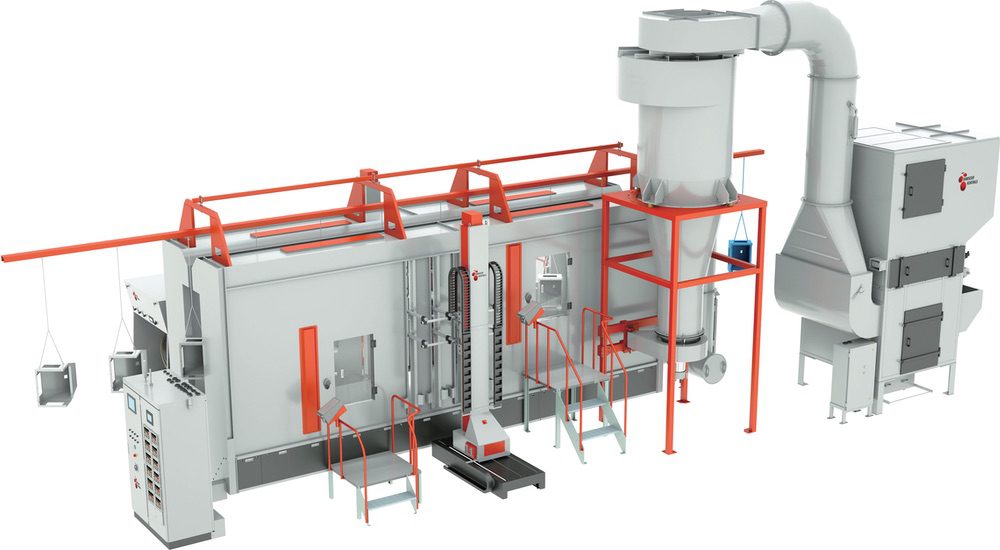

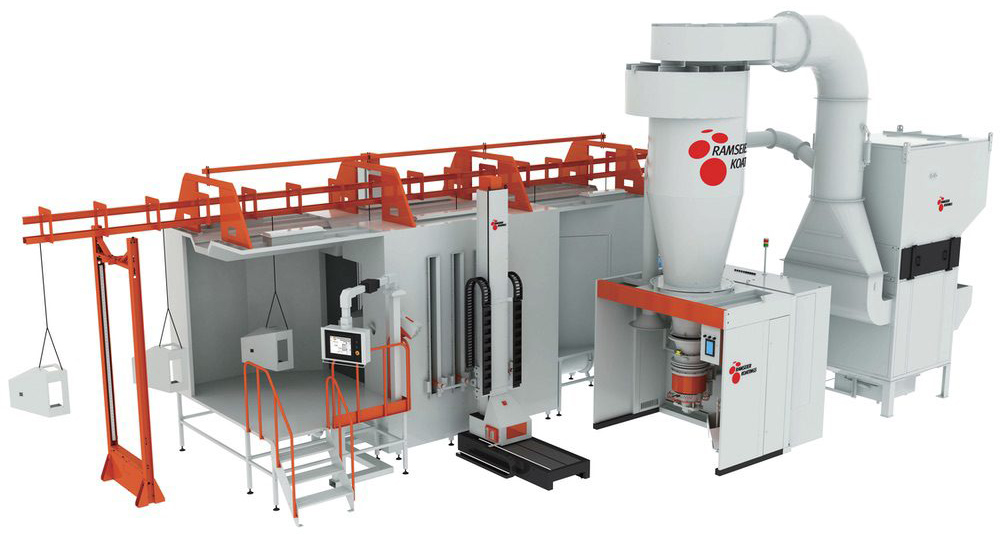

Now, let's talk about scale, people. The size of your operation matters big time. If you're running a massive operation, you'll want a high-efficiency machine. It's simple math, really. Bigger operation, faster production – you need a machine that can keep up.

But that's not all. Think about the product you're coating. Large and heavy? You'll need a machine that can handle the weight and size without breaking a sweat. And speed – the faster the operation, the more you'll appreciate a high-efficiency machine.

A high-quality powder coating machine doesn't just make your life easier; it makes your products look top-notch. We're talking about a smooth, even finish that's free of defects. Why does that matter? Well, it sets the parameters for standard, professional and good-looking finishes.

Also take note of durability. It follows that a high-quality machine will endure all the hard work thrown at it. You need not worry about costly replacements.

So, there you have it. It's not a walk in the park to have your powder coating paraphernalia set up.

You have got to figure out which ones to go with, electric or air. Electric commands a hefty price with the guarantee of top-notch quality. Air machines may be cheap but quality may not hit the mark.

Yet when it pertains shopping, how about you compare different prices, check on warranties and after sale services before you seal off the deal. But if it happens that you are on the fence a bit where to get your powder coating equipment, maybe it's time to pay a visit to Ramseier Koatings today. This is a one stop shopping experience for all the powder coating tools you need. The icing on the cake is that they have been here for about 30 years, and they got a stuff that's more than ready to guide you towards making the acquisition of tailor-made equipment that snugly fits your powder coating projects.