+852 2363 2511

Have you ever admired the smooth surfaces of cars, furniture, and other household items while wishing that your projects could be as perfect? Flawless appearances like these are given by powder coating. However, powder coating isn’t as easy a field to maneuver as it seems. While you may have found an experienced technician, attaining such flawless finishing is until dependent on one thing: equipment.

Powder coating guns are not all the same. The difference between okay results and outstanding finishes is often based on the caliber of your powder-coating gun. This change agent obsoletes traditional finishing techniques for both efficiency and cost-effectiveness. To unlock this game-changer potential, select a high-end powder-coating gun.

We have all had to go through the process of how we can get a perfect finish be it for DIY projects or big industrial applications. Finding an efficient and economical powder coat solution can be an overwhelming journey. Artisans will tell you that achieving those desired finishes requires more than just dexterity but having the right tools.

Welcome to the Ramseier Koatings, an epitome excellence in the powder coating industry. Backed up by a rich experience spanning over three decades, probably this the brand that has actually seen and influenced directly the changes cropping up over time in the technology of powder coating. It is not only the tools, but also the precision, reliability and innovative instruments that Ramseier Koatings makes that come along with their powder coating guns and equipment.

Powder coating most certainly does not stop at just the experience. It even gets better when experience meets dynamism as far technology advancements are concerned. Quality is an add on and good customer service. And if you have been looking for such, Ramseier Koatings makes it a possibility. Other reason to choose them include:

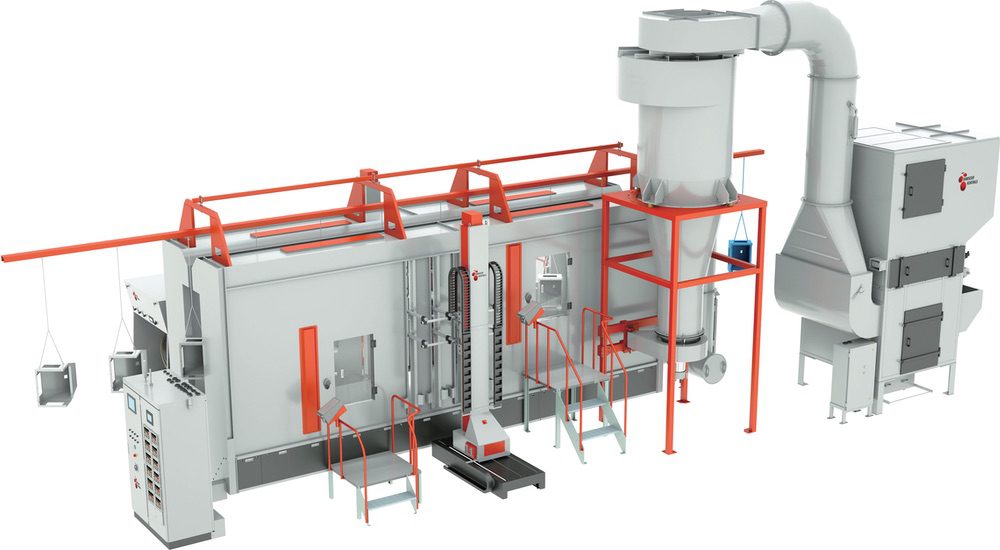

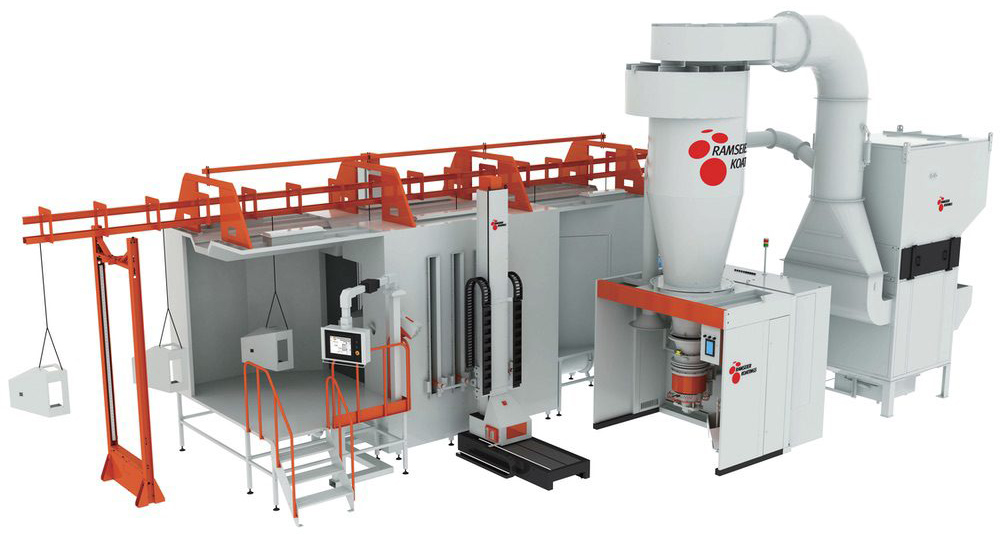

Ramseier Koatings offers a comprehensive portfolio of powder coating machinery, always with an orientation to the respective project and its specific individual requirements. With our assortment of powder coating equipment, whether you are a small DIY enthusiast having only one project or an industrial giant with complex coating needs, our devices cater to each and every need. Its versatility allows you to have the perfect tool for any rate through the hallmark of their equipment.

Ramseier Koatings has a rich history of trailblazing new technologies hence at the top of the powder coating technology. The mixture of Chinese and European experience, this forms a cauldron of knowledge that brings out nothing but state-of-the-art designs, as well as revolutionary features. When you opt for Ramseier Koatings, you do not purchase equipment, you buy decades of experience and the willingness to stay visionary.

The company has a global impact, but it is always committed to local communities even as it spread its influence across the globe. It’s also not just a tool that they designed with precision and care for; it represents the brand’s commitment to providing reliable solutions for customers globally.

Would you like to change your coating experience? Join us as we begin a journey into the depths of powder coating, uncovering Ramseier Koatings’ unique equipment features and armoring you with enough knowledge to make an accurate judgment on any of your projects. The more one learns about powder coating, the more one understands why Ramseier Koatings is the only choice for people who settle for nothing less than perfection.

First, let us demystify what powder coating entails before delving deeper into Ramseier Koatings’ specifics. What if there was a way to make surfaces visually appealing while at the same time making them more durable and resilient by adding an extra layer of protection? Powder coating is therefore a revolutionized process since it transforms finishes.

This simply means that powder coating is an application of granule on a surface to create a protective layer. These include glass, metal, plastic, steel, aluminum and even wood. So, what are the outcomes? It can be used to manufacture products like toys, electronics or even vehicle parts and furniture with more than just beauty.

During the last couple of decades, the process of powder coating has changed more than significantly and Ramseier Koatings has been well ahead in these alterations. They have high quality paint guns which are effective for home uses as well as in industries.

To begin with, the powder coating process involves spraying polymer or liquid metal onto a part using a spray booth or atomizer gun. If necessary, this leads to an additional layering for different colors or effects.

Once coated, the layered surface is dried so that the powder fully sets up. This keeps it from warping or melting later during production. Drying can occur inside a vacuum chamber or in an oven at temperatures between 200°C-250°C.

When it is dry, the substrate absorbs the powder coating and creates microscopic pores through which the atoms of the liquid bond chemically. This is an intricate process that ensures a long-lasting and durable finish.

There are different types of these devices in the market with varying pros, cons, and performance differences.

Metal laser-coating machines for industrial use ensure that powder coatings are applied accurately.

Powder coating booths are used in factories or other industrial settings where containers, plastic parts, flooring and furniture among others are coated. These things are hard to handle or move.

Like stationary powder coating machines but with wheels, mobile powder coating devices allow reaching difficult-to-access areas for operators not available using fixed models.

Automotive industry, electronics among others employ these for high-temperature processes. From lower temperatures for food packing to extreme temperatures, rotary furnaces and kilns cater to diverse needs.

The plasma arc chamber uses high voltage to heat its products and temperatures of these chambers range from 1300°C to 10000°C. They are used in glass coating, ready ceramics, finished protective coatings, finished steel and aluminum.

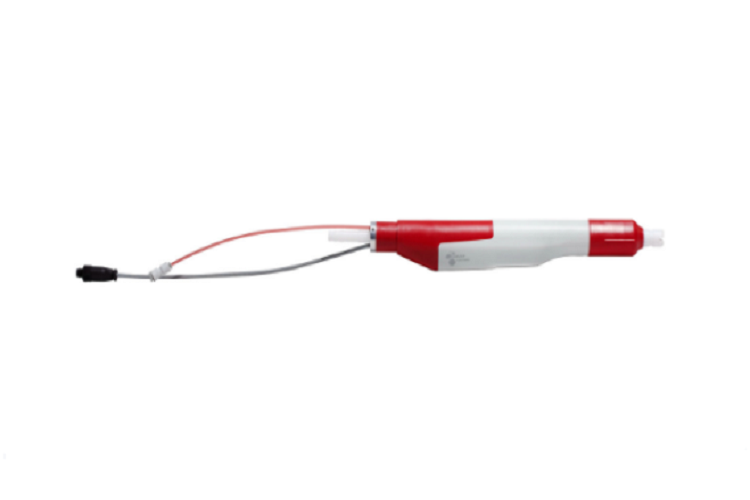

A good quality powder coating gun is essential to achieve uniform and smooth finishes consistently. These guns coat by powder electrostatically charging the powder and then curing it using heat.

It should be noted that there are two main types of powder coating units, each with its strengths and weaknesses; Tribo and Corona.

Best appearance possible applications, low charge conductivity surfaces, thin layering, touch up applications, epoxy coatings – all this is about tribo powder coating units.

Corona powder coating units perform best in the application of materials with higher charge conductivity levels or materials placed on surfaces not affected by Faraday cage regions like thick coatings as well as many custom coats.

Corona guns apply the high voltage generator in breaking up air to create positive and negative ions for creating charged powder cloud. As charged particles are attracted to the opposite pole (the part), the effective coating of the powder is done. Tribo guns charge the powder through physical contact and transport to ensure precision application.

Now that we together have ventured into labyrinths of art and mechanics associated with powder coating, followed by the forms of powder coating appliances, it becomes necessary to see what actually the difference is in Ramseier Koatings from same old run of the mill variety.

Ramseier Koatings is a reliable source of advanced, innovative, reliable powder coating equipment which has been in operation for over three decades. Its spraying equipment designed through continuous research and hard work boasts excellent reputation by those who use them.

Ramseier Koatings manufactures modern powder-coating guns with high-grade technology. The Europeans and China combined knowledge in powder coating guarantees designs develop user-centered and balanced to perfection.

Ramseier Koatings, the leading manufacturer of powder coating devices, offers a range of powder coating equipment to coat automobiles as well as metal, wood, and more. From manual devices to auto powder coating units, it provides all in a wide range to fit common requirements.

Ramseier Koatings holds patents on technologies such as the DDF Pump; wherein low speed, high density purposes are considered ideal for unadulterated soft impact spray. The Total Charge Control (TCC) electrostatics technology makes available for users’ choice between different charge modes on their machines.

Considering that each project is unique, Ramseier Koatings provides options for customization that enables users to customize their powder-coating gadgets according to specific project needs.

Presence of Ramseier Koatings in Switzerland, France, Germany, New Zealand, Italy, Thailand, Malaysia, Australia, Vietnam and several North African countries and the Philippines means that it has already gained a global recognition. The brand’s electrostatic painting industry has brought key advantages to these areas.

The quality of coating powders provided by Ramseier Koatings is beyond expectation. During application, the powder molecules level themselves up so that they do not run. This makes them have a more uniform coating than other liquid forms. Thus, fewer layers are needed thus preventing issues between layers.

Ramseier Koatings does not only provide high standard products but also guarantee safety and compliance as well. CE standards are met in the brands’ equipment which means its devices can safely assist people work effectively.

Powder coating at Ramseier Koatings process is non-toxic and reduces waste. Moreover, since there are no hazardous solvents or chemicals contained within this powder makes it safe for use and disposal. While expert painters take precautions, the overall process contributes to a safer and more eco-friendly coating solution.

Equipment delivery is not the only thing that Ramseier Koatings does. They put the interests of their customers first. For example, there is an elaborate customer service program that includes: trouble shooting, maintenance and repair. It also has spare tools and parts that are readily available thus allowing customers to easily access what they need to keep them running.

Ramseier Koatings still uses its core values like; belief in technology, quality commitment, management orientation and sincerity in service provision to give its clients superior knowledge and efficient coating solutions.

Being a reliable coating partner in the world today could be seen through years of experience and vast technical know-how. At Ramseier Koatings, for instance, we have an ongoing commitment to watch out for new developments and researches on fresh coating technologies aimed at improving our quality so as to maximize value for our customers.

In conclusion, choosing to enhance your coating experience with Ramseier Koatings is more than just about buying equipment; it’s about a drive for perfectionism. The company’s focus on quality and innovation is demonstrated by technology that has an impact across the globe as well as precise powder-coating guns.

Proceeding through the world of powder coating and offerings by Ramseier Koatings in this extensive exploration will empower you with the insights that assist you in making informed decisions. Therefore, Ramseier Koatings’ commitment to excellence supported by advanced technology and a customer-centric approach makes it a front-runner in the powder coating industry.

Your projects deserve the best, and with Ramseier Koatings, you’re not just choosing equipment; you’re choosing a partner dedicated to turning your coating endeavors into a harmonized process that produces flawless results. By examining every detail thoroughly, delving into subtleties, we can find out why Ramseier Koatings is always a top choice for finish perfectionists.