+852 2363 2511

Selecting the most suitable powder coating equipment is vital; Why? First these machines are worth a fortune and it would be so unfortunate if you bought the wrong ones. Additionally having the right equipment contributes to quality and productivity.

So, whether you intend to start a small-scale powder coating business, or want to compete in the big leagues, it is imperative to choose reliable equipment. This article will cover everything you need to consider when purchasing powder coating equipment.

But before we delve into the article, it is essential to know that powder coating isn’t a single step procedure; it involves several steps which is why you will require a few different pieces of equipment.

You will require equipment that will handle these three stages:

● Pre-treatment

● Powder coating

● Curing

As with most projects, the better the equipment quality, the better the results. So before you go spending your money, here are a few key considerations to take into account:

Products are just as good as the manufacturers. For this reason, it is important to evaluate the supplier before you invest. This will greatly impact the efficiency and quality of the powder coating procedure.

There are a few crucial factors that ought to steer your evaluation process. At the top of the list is reputation and experience. These two factors are incredibly helpful, because they tell you all you need to know about the supplier. A good track record is an excellent sign as it is a testament of a reliable supplier.

Next is the supplier’s range of products. This is vital since a wider collection gives you several choices, so you don’t have to settle.

Reliability and quality are also important factors. Choose suppliers who abide by the industry standards to ensure the equipment you purchase meets the required industry guidelines.

Good customer support should also be part of the list of considerations when choosing a reliable supplier. Seek a supplier who provides technical assistance, training and even maintenance services to guarantee flawless operation.

Finally, even though budget is a priority then quality should come before price. Purchasing top notch powder coating equipment can result in significant cost savings long term and boost overall performance.

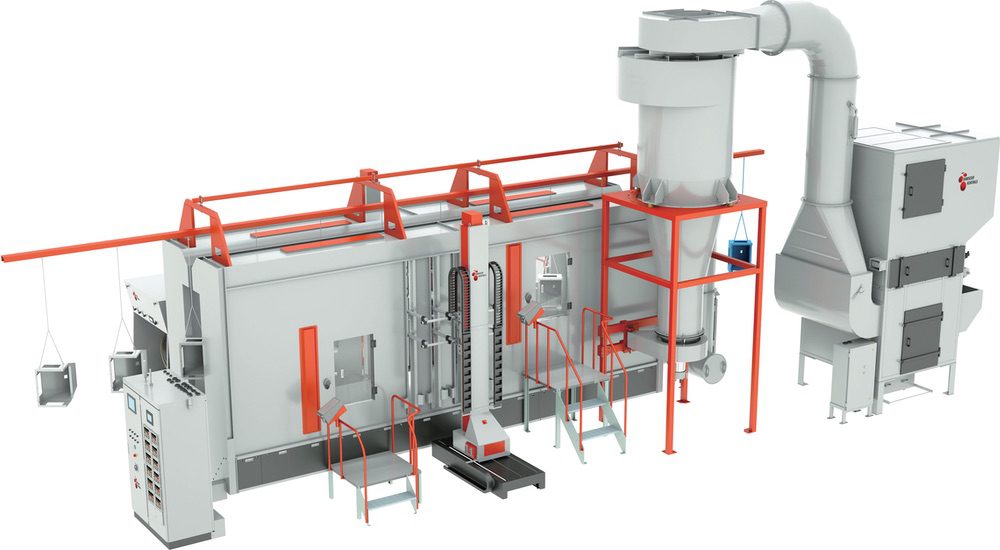

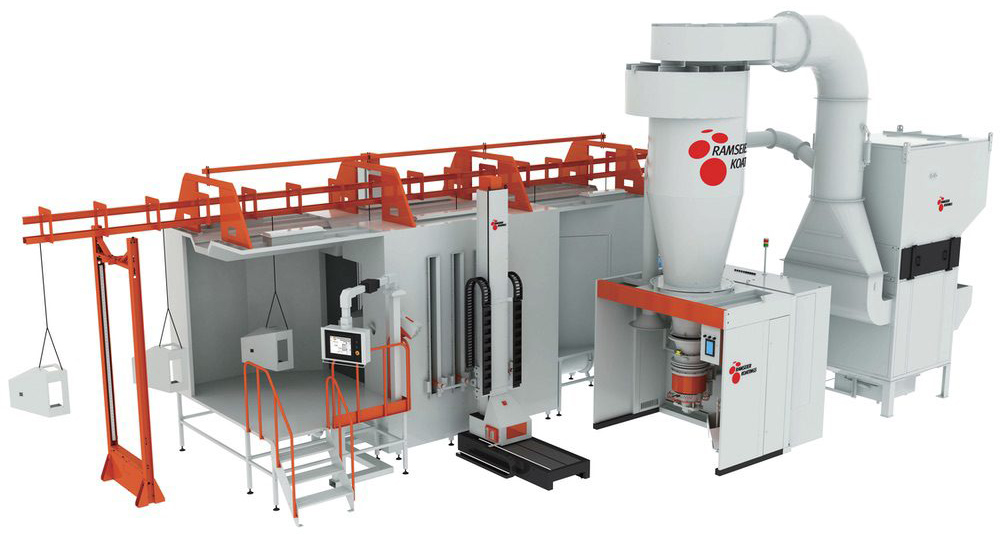

An automated system is the best way to go, if you’ll be working with many parts that have the same design. On the other hand, if you are working with parts with assorted sizes and shapes, you won’t find an automated system that helpful. In this case, it would be best to invest in a batch system.

Unfortunately, it requires employees to move the parts and put the powder coat on them. Therefore, if the parts to be produced are many, and require different settings, the batch system might not be of much help.

A batch system will come in handy, where the powder coating process is faster than the manufacturing process. On the other hand, if the powder coating process is slower than the manufacturing process, an automated system might be a better option.

An automated system lets you coat huge quantities of similar parts swiftly, because they don’ have to be checked by the workers between phases.