+852 2363 2511

Improved powder coating systems have been the best solution against traditional paints in terms of long-lasting features and cost-effective benefits. The coatings increase the product life, together with adding a certain element of durability, and they have a greater resistance to the elements and UV rays compared to the liquid finishes.

The process includes electrostatically spraying powdered part candidates to the surface, and then baked, coalescing to produce a hard, resilient finish. Pragmatically, the process includes a number of advantages that can largely assist in improving production efficacy and other tools and techniques in several ways. So, why would you opt for using powder coats?

Not that the coat would be made thick; no. The powder paint bonds excellently to make the layer tough and resilient. It will not chip, it will not peel, and it will scratch, and even when tough chemical compounds are exerted on it, it cannot scratch. This makes the products become long-lasting, and the owner will have reduced needs for maintenance.

This increases the life span and performance of products. Powder coatings will not yield in the wake of corrosion. You may just need it in marine settings and industrial settings.

Manufacturers are provided with increased design flexibility and customization options as powder coats come in various colors, textures as well as glossiness levels.

Get this: powder coating is almost VOC free and, comparatively associated with minimum emissions, which is not the case with trad paints. This, therefore guarantees lower rates of air pollution, safer work places for employees and that companies can meet the requirements of regulatory bodies. In addition, powder coating systems have greater efficacious rates. They won't waste to much paint and they ensure the paint sticks effectively.

The rapid growth in demand for fast-curing solutions has turned powder coatings into a leading finishing technology for industrial purposes. Powder coats do cure rapidly. It is not your run-of-the-mill latex paints that take eons to cure.

This means faster curing; therefore, it enhances productivity while reducing energy used, which is beneficial to manufacturing facilities’ sustainability drive.

With automation comes a reduction in labor costs. Manufacturers can make operations more efficient and reduce human error by automating coating procedures, providing better levels of uniformity across coating quality. Consequently, this leads to higher accuracy, consistency and money saving associated with labor expenses and improved production efficiency.

Automation, consistency, and higher accuracy rates mean less rework. This minimizes rework and touch-ups, reducing overall production costs and down time in manufacturing processes.

On top of this, the finishes applied by powder coats are consistent and long-lasting which means that products can still look appealing for quite a long period thus enhancing customer satisfaction as well as brand reputation.

Apart from cost savings and efficiency gains, powder coating systems offer flexibility in application. Materials such as metal, plastics and wood can use these systems thereby making them versatile enough for various manufacturing needs. This adaptability allows many manufacturers across a variety of industries to utilize the benefits of powder coating technology to improve product quality as well as endurance.

Powder coatings produce a smooth even coat on surfaces that enhances consumer appeal towards the related commodities. In industries where consumers consider aesthetics before deciding on what to purchase like the automotive sector, furniture industry, or architectural sector among others, powder coatings provide a competitive advantage.

There is production volume, workpiece size/complexity, finish specifications required, and production costs involved to be considered. Still, you might want to give the following a look.

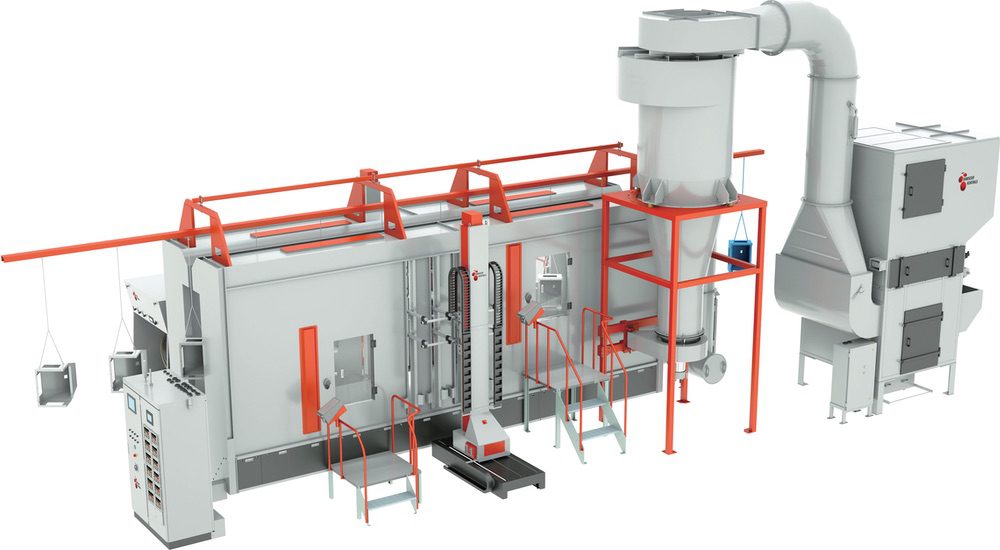

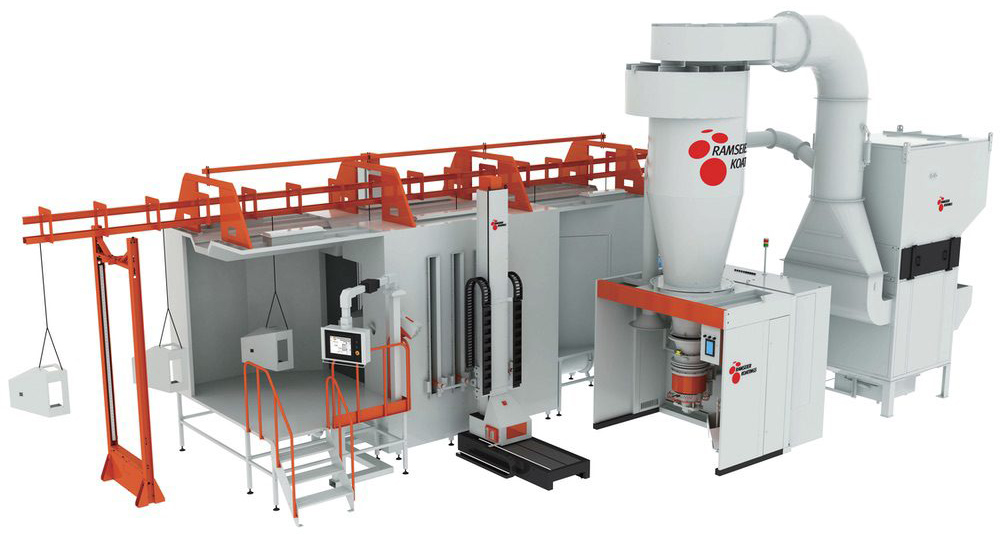

1. Spray Booth Size: This is where the spray booth matches up with the dimensions and quantities of workpieces for efficient coating operations.

2. Powder Coating Equipment: get to know your operation specifics and choose the powder equipment necessary to get the job accurately done

3. Automation Level: To determine how much automation may be needed; from manual to fully automated depending on available resources and the scale of production at hand.

In a nutshell investment in the system of a powder coated system basically assures manufacturers of a probable solution for product quality with respect to increased efficiency in production. It is comforting to know all these can be achieved even through automation: no single error from a human. This gives one more of a chance for the best in improving operational efficiencies, product quality, profitability and even a cutting edge above the competition.