+852 2363 2511

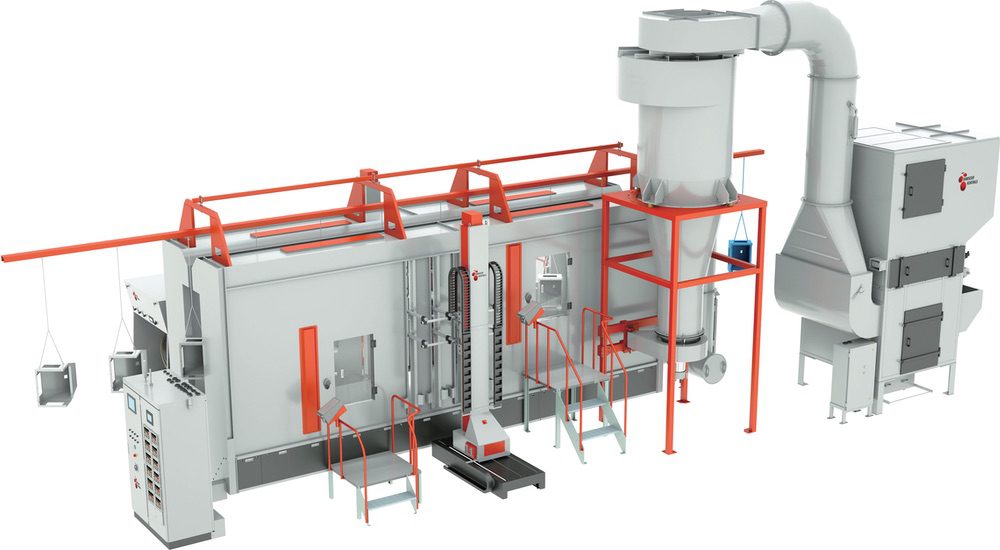

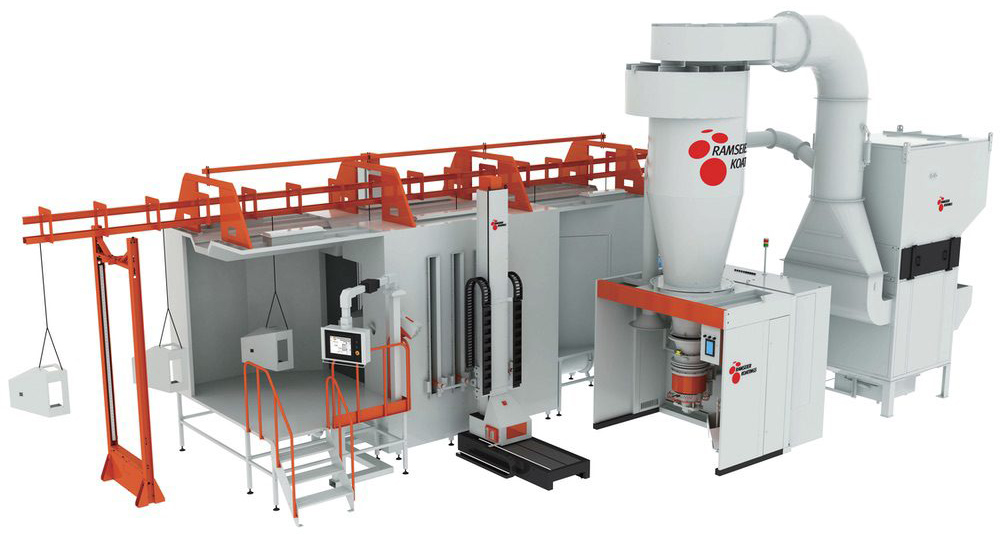

Knowing how to operate a powder coating machine is essential for producing professional-quality finishes for your metal parts. Powder coating machines are either automatic or manual. Automated machines are widely used since they increase output, but you'll have to pay more. Powder coatings adhere to surfaces by electrostatic charges.

You can use powder coating to achieve perfect finishes and durability than a paint finish. Spray booths, recovery systems, and cure ovens are common powder-coating machinery types. Keep reading if you're interested in using a powder coating machine but need help figuring out where to begin.

Powder coating is a finishing method that has grown in popularity since 1960. It refers to a type of surface finishing in which a fine layer of heated thermoset powder is spread evenly over a surface and is given time to harden. You can use this finishing method on a wide range of materials, like metals and plastics, accounting for a significant share of the finishing industry.

There are several steps involved in applying powder coating: prepping, applying, and curing. You can do any coating with equipment like a spray gun, booth, and curing oven. Also, understand your preferences, as powder coating may produce nearly any color.

You can go for either a solid, vibrant, or deep neutral color. Color blends are also suitable. If you do mass production, powder coating is equally effective.

A powder coating gun is required, and the spray guns come in various styles and models. To get the best results, always use a professional powder coating gun. Once you've decided on the most effective powder coating machines for your needs, you can proceed with the steps below.

You can only use the powder coating machine after you prepare your parts. The preparation step involves cleaning them to remove dirt and dust. The powder's ability to adhere to and improve the quality of your metal parts depends on how well you prepare the surface.

We can move on to the application if your surface is well prepared. You'll need to use a specialized Powder coating Spray Gun—the spray gun deposits particles with an electrostatic charge onto the substrate. Feed the powder in the electrostatic gun using the feeder device in the coating system.

Compressed air directs the powder into the gun from a powder chamber. The compressed air then releases the powder from the powder coating machine. The powder is electrostatically charged as it is expelled from the gun.

Once the expelled powder has been charged, it will cover the part adhering to the surface. A recovery system in the spray booth collects all the waste powder coat.

If you have successfully executed the application, you can move on to curing, which includes baking the powder-coated parts in a specialized oven. Cure the powder-coated metal parts at 400 degrees for around 30 minutes.

However, this time might vary substantially depending on your metal parts' shape, size, and coating thickness. The temperature in the oven remains constant once it has reached the required temperature.

Place the coated items in a chamber with carefully controlled air temperature for some time; until the pieces have cooled down after removal after the process is complete. Curing ovens use either electricity or gas. Traditional ovens use warm air that circulates over your parts, unlike advanced curing ovens.

Powder coating offers several benefits and advantages over other traditional liquid coating processes. A few examples are :

Powder coating your parts is a good idea because of all the advantages that come with it. Quality powder coating machines might cost you more, but they do the job! Powder coating is essential to the success of any business in the metal industry.

Before using your machinery, you must ensure it complies with local codes. You'll need some help powder coating if you don't have the necessary equipment. If you need powder coating services for a business or industry, contact Ramseier Koating.