+852 2363 2511

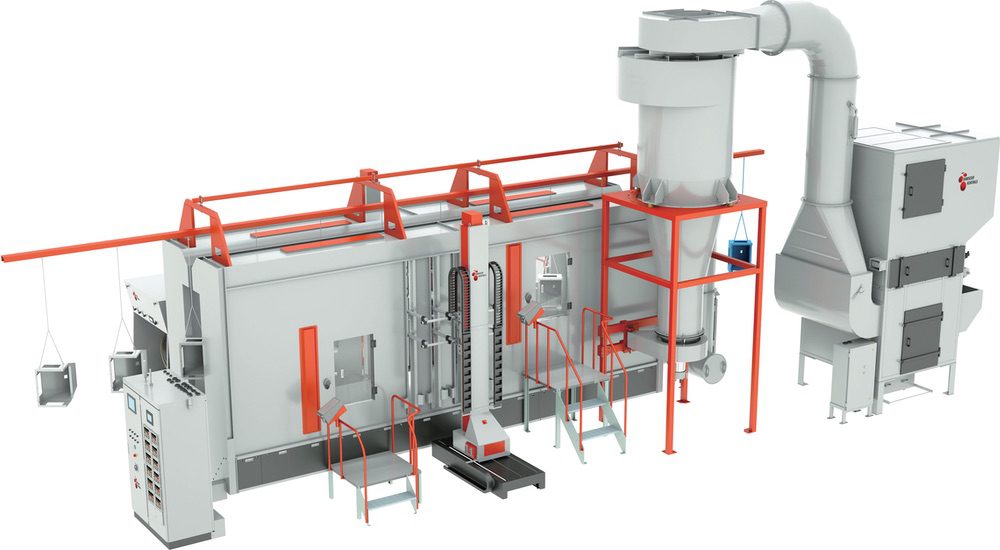

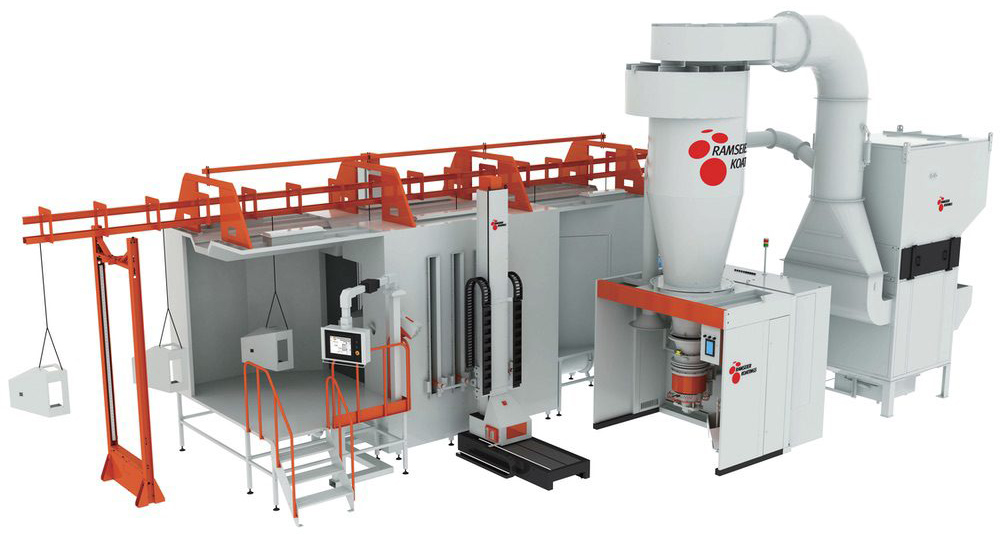

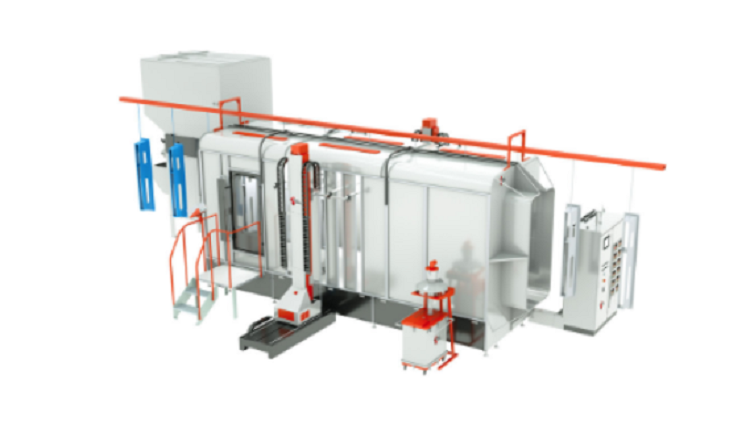

Powder coating is an eco-friendly and superior surface finishing technique that involves applying epoxy/polyester powder to an object's surface and heating to fuse into a protective layer. It can be done to metals and plastics. Basically, any object that can withstand 400 Fahrenheit can be powder coated. It typically involves three steps: pre-treatment, application, and curing. Blasting, washing, or wiping away dust, oils, debris, rust, and old paint/ finish makes the new material stick better. Finally, application and curing are done using special equipment. If you are new to powder coating and don’t know which equipment to buy, here is a look at some of the tools you might need. As already mentioned, powder coating is a three-step process, some can be accomplished with some improvisation, but others require special equipment. Here’s a look: Pre-treatment involves sandblasting, washing, or wiping away dirt, debris, oil, or old finishing to make the surface clean for the new coating. You can work in a blast room and use a massive air compressor or sandblaster to remove all the debris from the surface of the object. Other cases may require a wash station and pretreatment agents to remove chemical residues, oils, or solvents from the surface of objects. The washed parts must be heated in a dry-off oven to remove water from their surfaces before coating. Whichever way you decide to pre-treat the object, just ensure you achieve a clean surface before spraying the powder. You can invest in a sophisticated pre-treatment system if you plan to start a powder coating business. But an expensive pre-treatment system is unnecessary if you are just testing out the art. Powder coating units range from handheld guns to systems like the KMB Fast Color Change. They charge powder and spray it on the surface you want. The rate at which the units charge the powder is expressed in kilovolts (KV). Cheaper spray guns come with pre-selected KVs, while sophisticated systems allow users to choose. When selecting a powder coating unit, consider the coating material, project size, coating complexity, desired application speed, shop layout, and workflow. Some powders require higher voltages to transfer efficiently. Furthermore, a gun with a more precise and adaptable spray pattern will be more suitable if you want to apply a coat with complex colors and special effects. Automated guns are suitable for high-speed applications, and bigger guns suit bigger projects. Ensure the gun is easy to handle, comfortable to use, and fits your shop's layout and workflow. Depending on your local safety standard code, you may have to leave at least 3 ft of space between the walls and large powder coating plants. If you are new to the art of powder coating, start with a cheaper gun like the MG-S600. This won't cost you much. At this stage, the biggest limitation will be your skills, so don’t go for sophisticated systems. Try out cheaper, easy-to-use guns and see if powder coating is something you want to pursue. The final stage of powder coating involves heating to 450 Fahrenheit to fuse into a protective layer. Depending on your budget, you can go for an electric, LP-fueled, or natural gas-powered oven. Keep in mind the fuel usage, energy efficiency, and performance. Also, ensure the oven is big enough for the objects you want to powder coat. Your toaster or household oven will work fine if you are just trying out powder coating. You can also use a propane grill or insert a box extension to your household oven to make a ‘pregnant oven.’ But if you need high-quality curing, buy a professional oven. Powder coating is one of the best ways to give surfaces a protective finish, making them look better and last longer. It's eco-friendly and money-saving because the finishing is superior and durable. However, you will need a few special equipment for the job. Ramseier Koatings is one of the world’s leading manufacturers of state-of-the-art powder coating equipment. They have manual, automatic, and patented products like the Smart 600 electrostatic gun and the automated close-circuit powder management center for high-density, low-velocity powder coating. Get in touch with one of the company’s experts at +852 2363 2511 to learn more about their products.

Pre-treatment tools

Powder Coating Units

Powder coating ovens

Wrap-up