+852 2363 2511

Powder coating, as you know it, has gained a lot of recognition over the past few years as a cost-effective surface finishing technique that guarantees durability and aesthetics. But it has been mostly associated with metallic surfaces. So, the real question is, does it really powder coat plastic?

Yes, it does. In fact, powder coating plastics has been one of the most wanted methods nowadays in acquiring good-looking finishes. Read on to discover how different kinds of plastics are applicable for powder coating, the process involved in powder coating itself, as well as its many benefits.

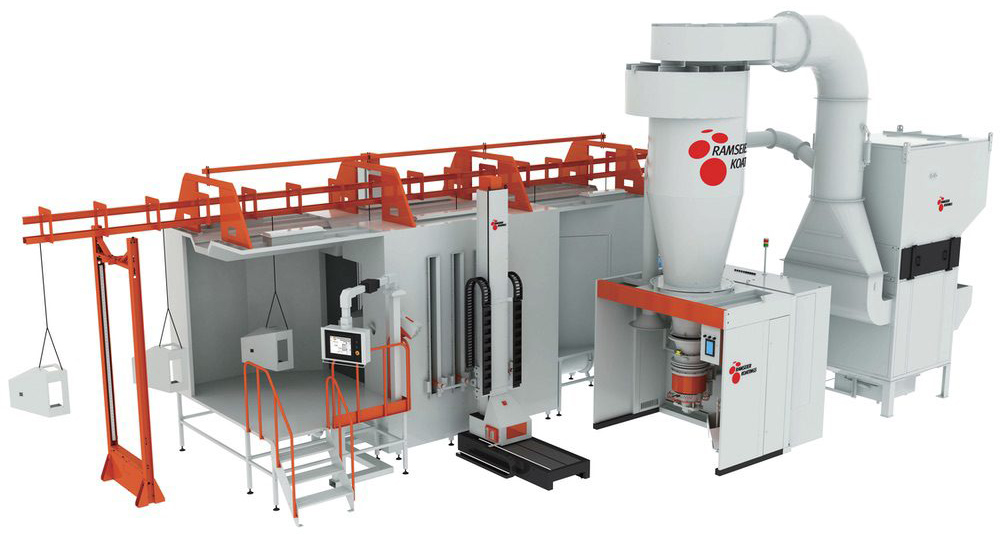

Powder coating can be done on metals which is the most common surface. Wood can also be powder coated and surprisingly plastic is also a contender. It involves application of dried paint pigment which is in powder form on the surface area of the material chosen. Th application is done by use of an electrostatic charge. Thereafter, this powder is heated up until melting for the purposes of creating a uniform coat which will provide protection from harm.

Traditionally, powder coating has been made popular with metals such as aluminum, steel, and brass. But with the recent developments, powder coating is becoming more popular with plastic materials. Suffice it to say, it offers an alternative to conventional paint that comes with a host of advantages. Powder-coated plastic boasts excellent resistance to abrasion properties, heightened durability property and good-looking finish hence high adorning aesthetics, as well as superiority in resisting chemicals.

Perhaps the most notable advantage of powder coating plastic is that it displays a strong and lasting finish, which considerably prolongs products' life over those coated using conventional paint. Additionally, when it comes to plastic materials using powder coating provides resistance, against chemical reactions and abrasion. This means that products made from plastic covered with powder coats are likely to be more durable and rigid.

Furthermore, the process of powder coating offers a finish that surpasses the quality of traditional paint. While painting plastic items does provide some protection it is prone to issues such as chipping, fading, scratching, as being vulnerable to extreme temperatures and moisture. On the hand powder coating plastics proves to be a choice with numerous advantages that make it a preferred option for manufacturers. It clearly stands out when it comes to long term protection.

Choosing the powder coating process is crucial for ensuring results in safeguarding plastic products against corrosion, abrasion and UV exposure. One such process is thermoset powder coating which involves applying and curing the material onto surfaces using heat. This method creates a bond between the plastic and the powder resulting in increased durability and protection.

Plastic products from this end can withstand harsh weather conditions and extreme temperatures effectively. Plus, they get to retain the shiny durable finish.

Contrasting with this, thermoplastic powder coating is where the powder is melted and then applied to the plastic product, which creates a strong bond between the two materials that enhances the strength and protection of the plastic. It is best suited for plastics that are intended to be powder coated and used indoors but exposed less to extreme heat. The method is better for particular types of plastic producing a flat appearance. However, it offers a less lasting finish even though it comes at a reduced cost. In this regard, understanding the nature of your plastic product will be important in determining the choice of powder coating you use.

As much as there are several benefits associated with powder coating plastics, some problems come along with this process. One of such challenges is curing. On account of low melting point for these plastics, curing them can be problematic unlike other materials like metals. The improved technology has simplified the process of applying paint on plastic surfaces. This includes using UV light exposure among others. Another one includes creating an attractive surface by treating the plastic with some material Manufacturers have also developed techniques to create a surface that promotes attraction by treating the plastic with a material. Therefore, this allows for better application of a coat on it.

It is true that powder coating is an enduring process to coat plastic parts and components. This process outperforms paint in terms of its lasting ability because it can face the harsh environmental conditions, high temperatures as well as UV light exposures. The method guarantees efficiency and is less expensive making it ideal for preventing rusting and corrosion of parts.

It is important to remember that powder coating plastics in the past was non-existent but gained popularity with time. It has many advantages including; reduced emissions, fewer layers needed and less waste produced. Besides giving a final coat, it’s also used for heat-sensitive materials.

In summary, thanks to the virtues of powder coating which makes plastics part of the world surface finishing. In case you ever wondered if you could use powder on plastics then look no more; besides the answer being a resounding yes it also comes with numerous advantages. Whether you choose thermoplastic power coating in order to save money or protect your environment as well as enhance the looks and strength of your plastic items at a very minimal cost.